Services

The company offers a complete service of subcontracting in the areas of electronic assemblies, starting from prototypes to small and medium productions using advanced technology and paying particular attention to the ongoing development of the electronics industry. We offer a service that starts from the acquisition of materials which your board will be made of, manufacturing using smt or pth technology, functional testing, assembly and conformal coating and finally the shipment directly to the customer.

Here are the details of our main services.

Managing raw materials

The raw materials are procured from official distributors or through the use of selected brokers if the parts are obsolete or hard to find. Everything is managed by an MRP system that provides us with all the information on prices and needed raw materials. Raw materials are labeled and located in 3 different areas of the warehouse: pth and smt customers.

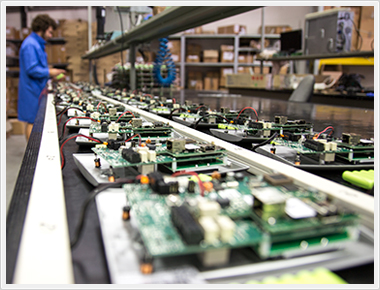

SMT production

Upstream of the SMT production process (Surface mounttechnology ) are two optical centering screen printers , a semi-automatic DEK 248 and a fully automatic DEK Horizon. The core of our production line consists of 3 Pick & Place : Assemblèon a Topaz, Assemblèon TopazX and a Assemblèon MG5. The process continues with two SMT reflow ovens: one forced air convection Ersa HotFlow5 and one vapor phase IBL BLC509. According to the requests of the customer or the amount / complexity of the product, optical inspections are done through a machine AOI ( Automated Optical Inspection) saky BF18D - P40 or 3 microscopes , one Leitz Wetzlar (Leica ) with 10X magnification , one with Labtek M700Z 31X magnification and a lynx Vision Dyneascope with magnification up to 40X and prism. The department has a production capacity of up to 52,000 components and is now able to mount components 0201 to about 100mm x 45mm boards with a minimum size of 52mm x 50mm x 0.2mm and maximum of 239mm x 390mm x 3.5mm.

Control X-Ray

In order to guarantee maximum reliability at every stage of processing, thanks to significant investments in resources in the areas of assembly and testing, we are able to offer an inspection service, with X-ray technology. To do this, we use a Vertex II V130 which allows the verification of the correct positioning and welding of components CSP, BGA, uBGA.

PTH production

The assembly of the traditional components is performed with 5 machines preforming STECKFUSS and placed into 2 groups for the "carrousel" pending the weld. Which is done with a welder wave IEMME Argo pond with Lead-Free SAC307. Provision is made in the same department, the finishing of the welding or manual welding is done by 4 workstations. The revision is done with Weller soldering irons and disordering PU81 PACE ST65. Cleaning and packaging of cards for shipment is the final part done in this section of the production.

Test & assembly systems

If the client requests, we can also carry out functional testing of the cards. On precise customer specifications, we are able to complete the product creating increasingly more complex systems, consisting of electronics, mechanical and wiring. Finally, if required, we handle the shipping directly to the end customer.

Conformal coating

The conformal coating, is a process which consists in coating the electronic boards with a light film of protective resin (in the order of a few microns), which allows to protect the board from the external environment, corrosion of the contacts, prevents short circuits and reduces the superficial ionic migration.

can be applied by brush, by dip or spray. Since 2013 we have automated the process with the purchase of ALPHA CU4 of AEB Robotics.